Materials selection in buildings is fundamental to low carbon design and construction. While many materials can make claims for sustainability, the case for using wool to sequester carbon is firmly rooted in science.

“Wool’s biogenic carbon content can comprise up to 50% of its weight,” notes Dr. Nilesh Bakshi, Lecturer in Architectural Science and Sustainable Systems Design, Wellington School of Architecture. “This boosts wool’s sustainability as a building material, and using it in construction helps transform the built environment into a carbon sink.”

Carbon-sequestering to meet lower emissions targets

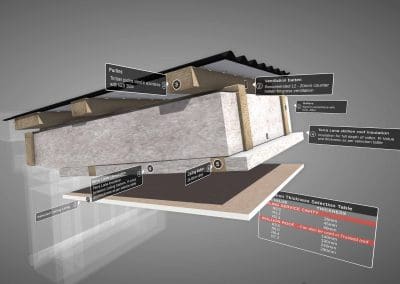

The world’s most stringent sustainability rating system, the Living Building Challenge (LBC), requires the use of only truly sustainable materials and building processes. For the Pā Reo building at Kāpiti Coast’s Te Wānanga o Raukawa, designed to the LBC Full Living standard by Tennent Brown Architects, Terra Lana wool insulation delivered across key criteria, such as carbon sequestering, product circularity, and high thermal performance.

Wool’s natural ability to sequester carbon along with Terra Lana’s ability to maintain it in a closed loop production cycle that recycles both production waste and end-of-life products, helps preserve carbon storage over time.

“Starting September 2024, new international standards for environmental product declarations will account for the biogenic carbon in materials like wool,” says Dr. Bakshi. “This change emphasises the value of incorporating wool into New Zealand’s construction industry for its carbon-sequestering benefits.”

Lowering both embodied and operating carbon

The primary focus of the MBIE’s Emissions Reduction Plan is to reduce the whole-of-life embodied carbon of buildings, accelerate the shift to low-carbon buildings, and improve their energy efficiency. Here, Terra Lana wool insulation excels in reducing both embodied and operational carbon.

“The carbon associated with a curtain wall or an intertenancy floor system is important to consider,” notes Dr. Bakshi, “but unlike those types of construction materials, Terra Lana’s insulation has a bigger job for two reasons.”

“One is its inherent impact on the embodied carbon of a building — what it takes to construct the building. But insulation also significantly affects operational energy and any carbon used during the building’s lifetime.”

“Wool isn’t a better insulator because of its R-value or its ability to create higher thermal resistance — though it performs well in that regard too. Wool is a superior insulator due to its natural, organic qualities and the fact that we live in a region where moisture is an inherent part of our climate.”

“Other types of insulation, especially those that aren’t nature-based, don’t perform well when they get wet. Once wet, they fail to perform at the specified value. Wool materials don’t have that issue; wool excels at absorbing and releasing water vapour, while retaining thermal resistivity.”

“This doesn’t just refer to leaky buildings; it also applies to environments with high humidity or interstitial moisture, which are becoming increasingly important with climate change and peak wet weather events. Buildings need to be designed to manage internal and external moisture to keep the structure dry.”

Local materials, circularity and custom manufacture mean less waste and fewer carbon miles

Another area where specifying Terra Lana wool insulation delivers is in waste diversion, with the LBC requiring a 95 percent diversion for insulation and carpet waste.

“This was a real plus for the Pā Reo building,” notes architect Ewan Brown. “Terra Lana could manufacture the insulation pads to the exact width needed to fit the joists, resulting in very little waste on site. The few off-cuts were returned to the factory for recycling — not downcycling, but reintegrated into the same quality product.”

For Dr. Bakshi, Terra Lana’s contribution to lowering both embodied and operational carbon is built into its raw material, combined with its local production. “The fact that it’s manufactured in New Zealand means you’re winning half the battle already because it’s better to use that material than to ship products here.”

Talk to our team

Contact the Terra Lana team to find out which Terra Lana product is right for your project. Email spec@terralana.co.nz or phone 0800 485 262.