Located adjacent to Lincoln University, the Tuhiraki AgResearch facility unites nearly 300 scientists and support staff, fostering collaboration in agricultural science and innovation. The facility’s emphasis on locally-made wool products, such as Terra Lana insulation, reflects a perfect synergy between product and client, contributing to the country’s economic growth.

Given AgResearch’s world-leading expertise in the consumer-relevant attributes of wool and the farm systems that produce it, the inclusion of wool insulation (and carpet) in the new facility was a key requirement from the outset.

Sustainability principles meet practical application

With an understanding of AgResearch’s own findings about wool, and hands-on research with Terra Lana, the architects recognised the advantages Terra Lana insulation would bring to the project.

They participated in a factory tour during the design phase to explore the benefits of wool insulation, including its moisture absorption and release capabilities without compromising insulating properties, preventing issues like material degradation. They also saw how wool batts maintain their loft over time.

With Terra Lana insulation’s environmental benefits, health and safety advantages during handling, and manufacturing circularity at end-of-life, the products aligned with sustainability principles for the project and would provide excellent thermal and acoustic comfort for Tuhiraki AgResearch’s people.

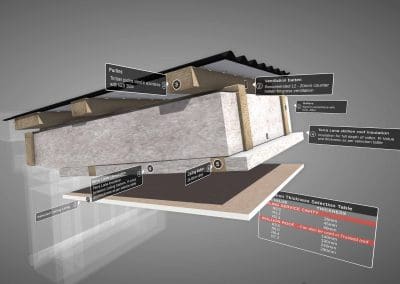

Primarily used in the Workplace Wing, Terra Lana wool insulation was installed in the external walls for thermal insulation, within the raised floor for acoustic insulation, and inside meeting room partition walls and meeting room pod ceilings. It was also used in some laboratory plant room level spaces for ceiling and external wall thermal insulation.

A locally sourced product to support future generations

During installation, Terra Lana again demonstrated its effectiveness. Its self-supportive nature allows for excellent friction fit, doesn’t slump, and makes it easier to create check-outs around services where necessary, while still maintaining its thermal integrity.

The architects appreciated that the product to be ordered in custom widths and offcuts returned for recycling, which was a green tick for minimising waste during construction.

By choosing locally-sourced wool insulation, the project minimises the carbon footprint of a building and reduces environmental impact, particularly in terms of end-of-life waste. This supports sustainable practices by promoting the use of renewable, biodegradable materials that have a lower ecological impact throughout their lifecycle.

With the Tuhiraki facility poised to generate significant new research to support farming in the district and beyond and attract future generations of scientists, its lifecycle is set to be long and productive.

Talk to our team

Contact our team to find out which Terra Lana product is right for your project. Email us at spec@terralana.co.nz or you can phone us on 0800 485 262.

Project credits

Product: Terra Lana wool insulation

Builder: Leighs Construction

Photographer: Sarah Rowlands

Writer: Folio